Webinar: How can we deliver 4000 m MD wells in 10 days on NCS?

Welcome to the first webinar of 2021 for Production Optimization and Reservoir Managment network group. Raghu Kulkarni from Equinor is asking the question: How can we deliver 4000 m MD wells in 10 days on NCS?

| Date | Time | Duration | Register by | Location |

| 18.02.21 | 13:00 | 60 min | 17.02.21 | Teams |

Speaker: Raghu Kulkarni, Sr Advisor Res Tech, Equinor

Abstract:

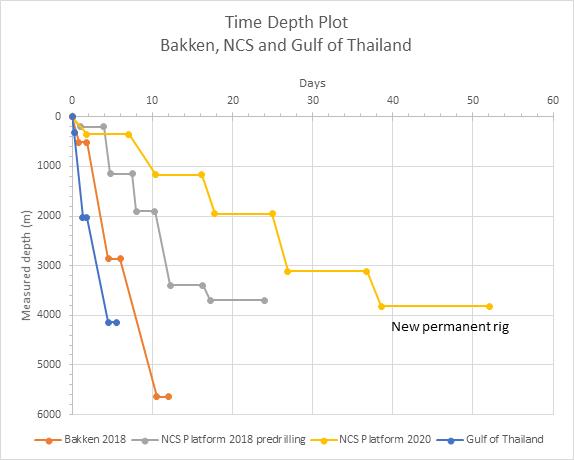

We see many examples in the world where existential threats have sparked innovation leading to a radical improvement in efficiency of legacy oil field operations. US onshore innovated itself out of disappearingly small production in 2010 to producing 8.5 million barrels per day at peak in 2020. Between 2010 and 2018, US Onshore drilled 10000 wells a year, delivering 6000 m MD wells in ca 12 days and a drilling cost of ca 2 MUSD. While many will discount this performance as limited to USA and to onshore operations, a similar radical innovation has been accomplished in Gulf of Thailand, in 60-100m water depth conventional offshore fields (reservoir temperature 170-200 Celsius, pressure 1 – 1.5 sg). Some 8000 wells are drilled in last 20 years with ever improving efficiency. A 4000 mMD well fully completed is delivered in 6-8 days and at a cost of ca 2 MUSD. In contrast, Norway fixed platform well take 50+ days to deliver a 4000 m MD well at ca 20 MUSD price tag.

In both these places, there is a big focus on time efficiency, critical path and assembly line. Just like a car factory, where output at end is measured, in how many finished cars that are produced per year, the 2 regions focus on assembly line and parallelizing activities to get efficiency and deliver more wells per year driving efficiency in supply chain. As all equipment and human resources in the supply chain get used more effectively per year, the cost per well falls, while still maintaining similar profitability for suppliers as well as operators. Such efficiency gains are fundamental to have profitable oil and gas production in lower for longer oil prices and smaller and smaller well targets and discoveries.

The presentation will focus on comparing time vs depth plots of these regions and delve on some of the technologies that can and should be adopted on NCS dry wellhead platforms. The three key technologies used are slim wells, conductor sharing wellheads and offline/batch well drilling. The offshore operations are conducted with 2 barrier philosophy just as on NCS through innovations focused on time efficiency and safety. Despite the enormous geographical spread of these regions, and the spread in number of days used to deliver a complete well, the drilling speed (m/day) while the bit is rotating is similar in these 3 regions. Some open ended questions on porting these technologies to subsea will be discussed.

An exercise of well planning using 2 independent teams, one in US Onshore and one on a NCS platform, was conducted to plan a well on the platform using same starting point, design basis (pore-pressure, well path, formation data, and expected rates). An analysis of the observed differences in time and cost will be presented.

References

Attendees encouraged to pre-read at least Abstract, Introduction and Conclusions of references 1, 3 and 5 together with the 4 minute youtube video.

Offline Operations

- Pushing Malaysia's Drilling Industry into a New Frontier: How a Distinctive Wellhead Design Enable Implementation of a Fully Offline Well Cementing Resulting in Significant Shift in Operational Efficiency, SPE 202439, 2020.

- Faster, Deeper, Cheaper – Slimhole Well Construction in the Gulf of Thailand, SPE 90999, 2004.

- Under-Rig-Floor Openhole Logging in the Gulf of Thailand—Engineering Design of the Oil Industry’s First Simultaneous Openhole Wireline Logging and Drilling Operation, SPE 116335, SPE Drillling and Completion Journal, March 2010.

Splitter wellhead technology

- Splitter wellhead video (youtube)

Slimhole

How a webinar works

You register as usual through the registration button above. Once you are registered you will get an invitation via email to join this webinar.

FORCE uses Teams Video for this webinar, and has proven to work successfully.

We recomment that everyone joining turn off their camera and microphone when joining.

If you have any questions you can use the chat or wait until the end of the talk.

FORCE seminars have previously been fully booked with waiting lists so you are encouraged to sign up as soon as you know you will attend.

Participation fees:

FORCE members: Free

Non-members: NOK 350,-

University/student: Free

Important information:

You can register as a FORCE member and pay "FORCE member" price if you are an employee of a member company.

All FORCE member companies are listed here.

Payment is made online by credit card. Please note that no refunds will be given after you have signed up.

If you for any reason can not attend the workshop, you are welcome to send a representative, just inform Linn Smerud as soon as there are changes.

If you have any questions please contact Linn Smerud at the FORCE secretariat.

Updated: 2/19/2021