Decommissioning costs

Chapter 5: Cessation

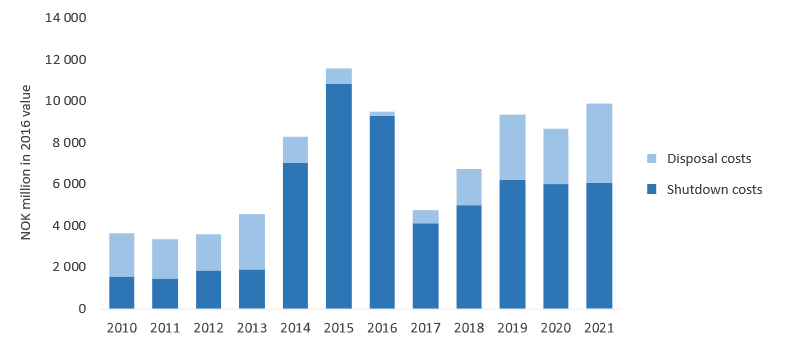

The costs relating to shut down and disposal are relatively small compared with expenditures on exploration, development and operation and with the revenues it generates. Shutdown and disposal costs over the past five years totalled NOK 32.5 billion and NOK 8.5 billion respectively in 2016 value. The NPD expects the corresponding figures for the next five years, again in 2016 value, to be NOK 23.4 billion and NOK 12 billion.

In the figure above, cessation costs for 2010-15 represent actual figures while those for 2016-21 are forecasts from the revised national budget (RNB) for 2017. A rise in these costs is expected from 2018-19, which also accords with an increase in the level of activity in disposal of facilities.

Cessation costs is a broad term, and incorporates preparatory expenditures on fields due to come off stream as well as spending on shutting them down and plugging their wells. In addition, it includes costs for necessary clearing up on fields which are not scheduled to come off stream during the period. Disposal costs relate to implementing the physical removal or abandonment of facilities.

During 2011-21, cessation costs will account for three per cent of the NOK 2 733 billion actually used or due to be spent on petroleum activities. This overall amount breaks down as:

- 58 per cent Investment

- 24 per cent operating costs

- 12 per cent exploration costs

- three per cent cessation costs

- three per cent other costs.

This proportion will probably rise when the big fields come to shut down

Shutdown costs

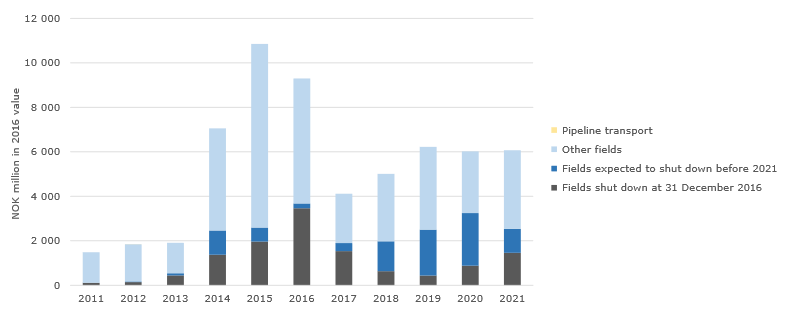

Shutdown costs in 2015 were up by 54 per cent from the year before. But that was not because more fields came off stream as a result of low oil prices. Most of the 2015 figure is costs related to plugging of wells and removing equipment no longer in use from fields on stream. The biggest contributors included Ekofisk, Eldfisk and Statfjord.

A large part of shutdown costs relate to fields which will remain on stream for many years to come (light blue).

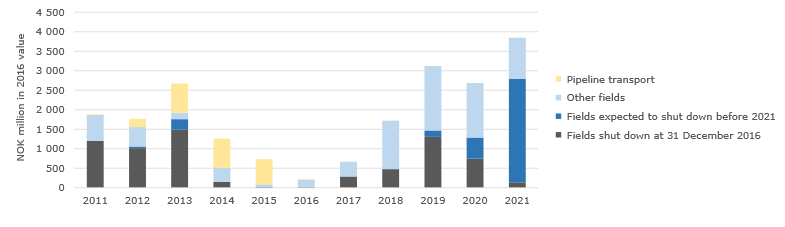

Disposal costs

Although total shutdown spending rose in 2015, disposal costs declined. The pipeline transport category includes the removal of the B11 compression platform. This formed part of the Norpipe system from Ekofisk to Emden in Germany, and was removed because the need for gas compression in this pipeline had declined since the platform became operational in 1977.

Disposal costs.

Uncertain forcasts

Considerable uncertainty prevails over the forecasts for future shutdown and disposal costs. The material condition of facilities, market volatility, industry experience, expertise and knowledge, capacity of the service and supply industry, and technology development are among the factors which will affect the cost Picture.

As more disposal projects are executed, the government and the industry will acquire further information which can help to provide a more precise picture of the future costs.

Although the cost of removing facilities and plugging wells is likely to decline through learning and technology development, overall disposal expenditure will probably be somewhat higher in the long term. Good collaboration between licensees, service and supply industry, government and relevant interest organisations will be important for the best possible disposal solution, and thereby for reduced costs.

Historical breakdown of costs

Total expenditure on fields where production had ceased at 31 December 2016 was NOK 428 billion in 2016 value. Field developments vary considerably in terms of size, complexity and number of installations. Big differences in disposal costs will therefore exist between a field with a single subsea template and a development with one or more large facilities. Costs for big disposal projects will be spread over a longer period than for a field with small and simple development solutions

Shutdown and disposal costs on fields which have now ceased production range between three and 15 per cent of total expenditure.

On average, eight per cent of total costs relate to shutdown and disposal on fields which have ceased production.

Costs of well plugging

All wells on the Norwegian continental shelf (NCS) must be permanently plugged and abandoned (P&A) in an acceptable manner. Plugging costs per well can vary from just under NOK 50 million to several hundred million kroner. This depends on the complexity of the field and the wells. Based on figures reported by the companies, the NPD has estimated that 40-50 wells are due to be plugged annually over the next few years.

A dedicated forum for P&A of wells was created in 2009 by the Norwegian Oil and Gas Association to exchange experience between a number of companies and fields. Examples include operational P&A experience from Ekofisk/Valhall and work on the barrier philosophy for Ekofisk and Huldra. Efforts are being made to develop simpler and more cost-effective well-plugging solutions.

Breakdown of cessation costs

![kuttestaal-1[1].jpg](/49e3c0/contentassets/7eaa153528df48eca67cdc288da6b112/kuttestaal-11.jpg)

Cessation gives rise to various types of activities. Costs related to cessation are broken down below between various expenditure categories.

55-85 per cent: offshore

The biggest expenditure relates to removal of facilities offshore and permanently plugging and abandoning wells.

5-20 per cent: operation

Operating costs cover maintenance of facilities from shutdown until final disposal offshore. Shortening this period could reduce costs while making the actual removal and scrapping work more efficient.

5-15 per cent: onshore

The onshore cost category covers waste treatment and recycling on land, including cleaning and treatment of hazardous waste, scrapping, re-use, recycling and deposition.

5-10 per cent: administration

Administrative costs cover the company’s own spending on its organisation for preparing and executing decomissioning projects, and on external studies in an early planning phase