A brief description of EOR methods

Chapter 3: Technical potential

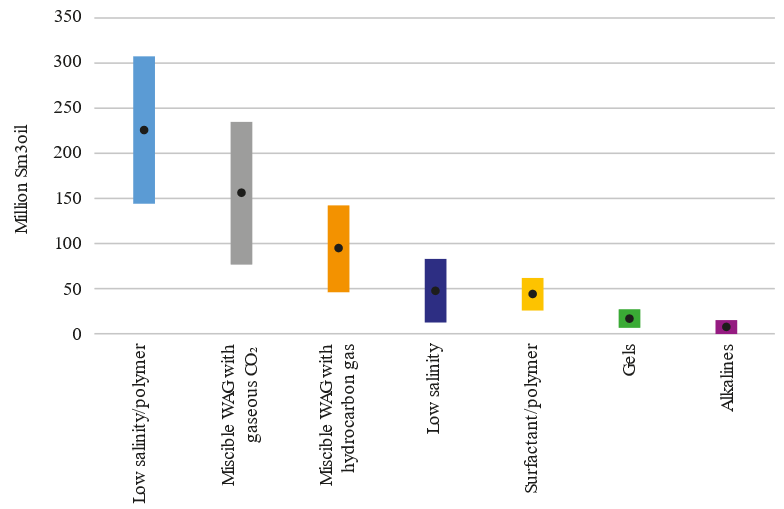

The NPD has conducted a screening study in cooperation with London’s Imperial College to identify the technical potential for enhanced oil recovery (EOR). A total of 13 methods were assessed for 27 of the largest oil fields on the Norwegian continental shelf (NCS). Only the EOR solution with the biggest potential for each field was chosen. That yielded seven Methods.

These are outlined below in descending order of their potential in the study (highest to lowest).

The NPD has acquired relevant reservoir and production information for the fields in question. That provides input data for the model used to estimate the technical EOR potential. This uses mapping criteria and improved recovery factors based on an extensive literature study as well as data from the industry and research experience.

MORE INFORMATION: Details of the study and how the potential is calculated.

Low salinity/polymer flooding

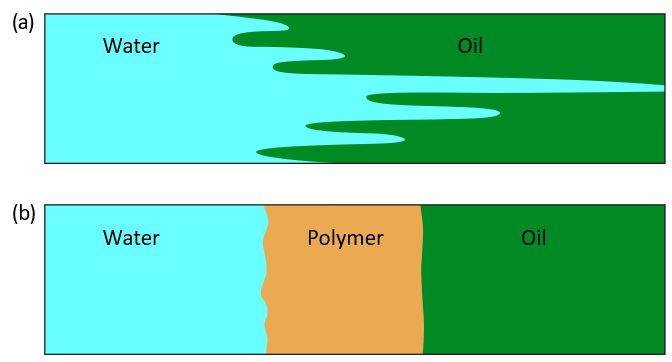

This method involves injecting a combination of water with reduced salinity and polymers. Adding polymers to injection water raises the viscosity of the water (thickens it), which gives a more stable and even displacement of the oil. Low salinity – in other words, injection water with a reduced salt content – can alter the wetting state of the rock and reduce oil-water interfacial tension, which mobilises more of the immobile oil for production. It also provides other benefits, such as reduced risk of acidification in the reservoir and downhole deposition of precipitated chemicals. In addition, the quantity of polymer needed to obtain the desired viscosity can be reduced.

A simplified presentation of the difference between water (a) and polymer (b) flooding.

Miscible WAG injection with CO2

Providing CO2 supplies are available for injection, miscible CO2 water alternating gas (WAG) injection will be an effective EOR method.

Under miscible conditions (which depend in part on pressure, temperature and oil composition), CO2 and oil will dissolve in each other to form a single phase. This reduces the viscosity of the oil as well as interfacial surface tension between oil and gas. These processes mean that the oil can be driven more easily towards the production wells and recovered. In addition. part of the immobile oil could be mobilised and thereby produced.

Alternating injection of CO2 and water reduces gas consumption while also providing displacement and pressure-support benefits for the water. Another advantage is that part of the CO2 will be permanently left behind in the reservoir

Miscible WAG with hydrocarbon gas

This method works in the same way as miscible CO2 WAG, but using hydrocarbon gas instead. The latter has the drawback when compared with CO2 that miscibility is often more difficult to achieve. Moreover, the gas could have a substantial sales value.

The video illustrates gas-based EOR Methods.

Low salinity flooding

Changing the chemical composition of the injection water to reduce its salinity can alter the wettability of the reservoir. This could help to mobilise part of the immobile oil for production. Other benefits could include reduced risk of acidification in the reservoir and downhole deposition of precipitated Chemicals

Combined surfactant and polymer flooding

This method involves injecting a combination of surfactants and polymers. Adding polymers to injection water increases the viscosity of the water, which gives a more stable and even displacement of the oil.

Surfactant is added to injected water to alter the wetting state of the rock and reduce oil-water interfacial tension, thus mobilising more oil from the pores. The video below includes an explanation of how immobile oil can be mobilised with the aid of surfactants.

The video illustrates water-based EOR Methods

Gels

If the reservoir is heterogeneous in the sense that it has highly permeable zones or strata, injected water may flow through these layers from injection to production well. A lot of oil will be left behind when the water reaches the production well. The highly permeable zone can be sealed off by setting a plug of gel which forces the water into the surrounding undrained areas.

Alkaline flooding

Alkaline substances added to the injection water react with the oil to reduce oil-water interfacial tension and alter the wettability of the reservoir. That could increase oil Production

Technical potential by EOR method

Mid-range estimates and uncertainty ranges for the methods included in the technical EOR potential.