3.3 - Workflow and characterization

Characterization

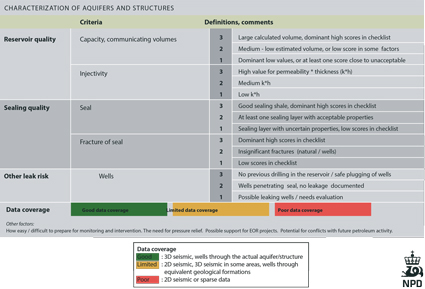

Aquifers and structures have been characterized in terms of capacity, injectivity and safe storage of CO2. To complete the characterization, the aquifers are also evaluated according to the data coverage and their technical maturity. Some guidelines (a check list) were developed to facilitate characterization. Parameters used in the characterization process are based on data and experience from the petroleum activity on the NCS and the fact that CO2 should be stored in the supercritical phase to obtain the most efficient and safest storage.

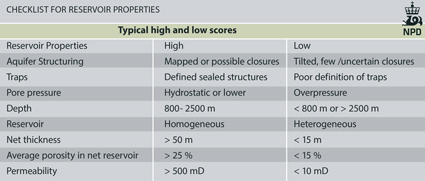

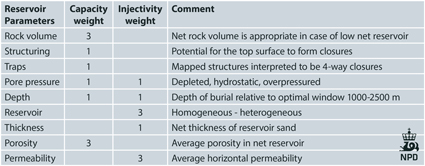

The scores for capacity, injectivity and seal quality are based on evaluation of each aquifer/structure. The checklist for reservoir properties gives a more detailed overview of the important parameters regarding the quality of the reservoir.

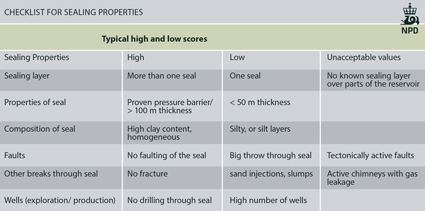

Important elements when evaluating reservoir properties are aquifer structuring, traps, the thickness and permeability of the reservoir. A corresponding checklist has been developed for the sealing properties. Evaluation of faults and fractures through the seal, in addition to old wells penetrating the seal, provides important information on the sealing quality. An extensive database has been available for this evaluation. Nevertheless, evaluation of some areas is more uncertain due to limited seismic coverage and no well information. The data coverage is colour-coded to illustrate the data available for each aquifer/structure. Characterization and capacity estimates will obviously be more uncertain when data coverage is poor.

Fig.3.08

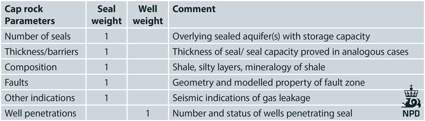

The scores for capacity, injectivity and seal were determined from the individual parameters established in the guidelines. Each parameter was given a score, and the scores were combined to give the final score for the aquifer. Some parameters were weighted, as shown in the tables.

The methods used for characterization of reservoir properties are similar to well-established methods used in petroleum exploration. Characterization of cap rock and injectivity is typically conducted in studies of field develop-ment and to some extent in basin modelling. For evaluation of regional aquifers in CO2 storage studies, the mineralogical composition and the petrophysical properties of the cap rocks are rarely well known. In order to characterize the sealing capacity in this atlas, we have mainly relied on regional pore pressure distributions and data from leak-off tests combined with observations of natural gas seeps.

Fig.3.09

Fig.3.10

Fig.3.11

Fig.3.12

In exploration wells on the Norwegian shelf, pressure differences across faults and between reservoir formations and reservoir segments are commonly observed. Such pressure differences give indications of the sealing properties of cap rocks and faults. Based on such observations in the hydrocarbon provinces, combined with a general geological understanding, one can use the sealing properties in explored areas to predict the properties in less explored or undrilled areas.

Natural seepage of gas is commonly observed in the hydrocarbon provinces in the Norwegian continental shelf. Such seepage is expected from structures and hydrocarbon source rocks where the pore pressure is close to or exceeds the fracture gradient. Seepage at the sea floor can be recognized by biological activity and by free gas bubbles. Seismically, seepage is indicated by gas chimneys or pipe structures. The seepage rates at the surface show that the volumes of escaped gas through a shale or clay dominated overburden are small in a time scale of a few thousand years. Rapid leakage can only take place if open conduits are established to the sea floor. Such conduits could be created along wellbores or by reactivation of faults or fractures. Established natural seepage systems are also regarded as a risk factor for CO2 injection.

In summary, the capacity of each aquifer is given in the tables as a deterministic volume. The injectivity and sealing properties are indicated by scores 1 to 3. The characterization is based on a best estimate of each parameter. Uncertainty is not quantified, but is indicated by the colour coding for data availability and maturity.

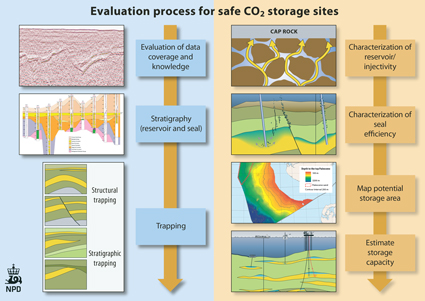

Workflow

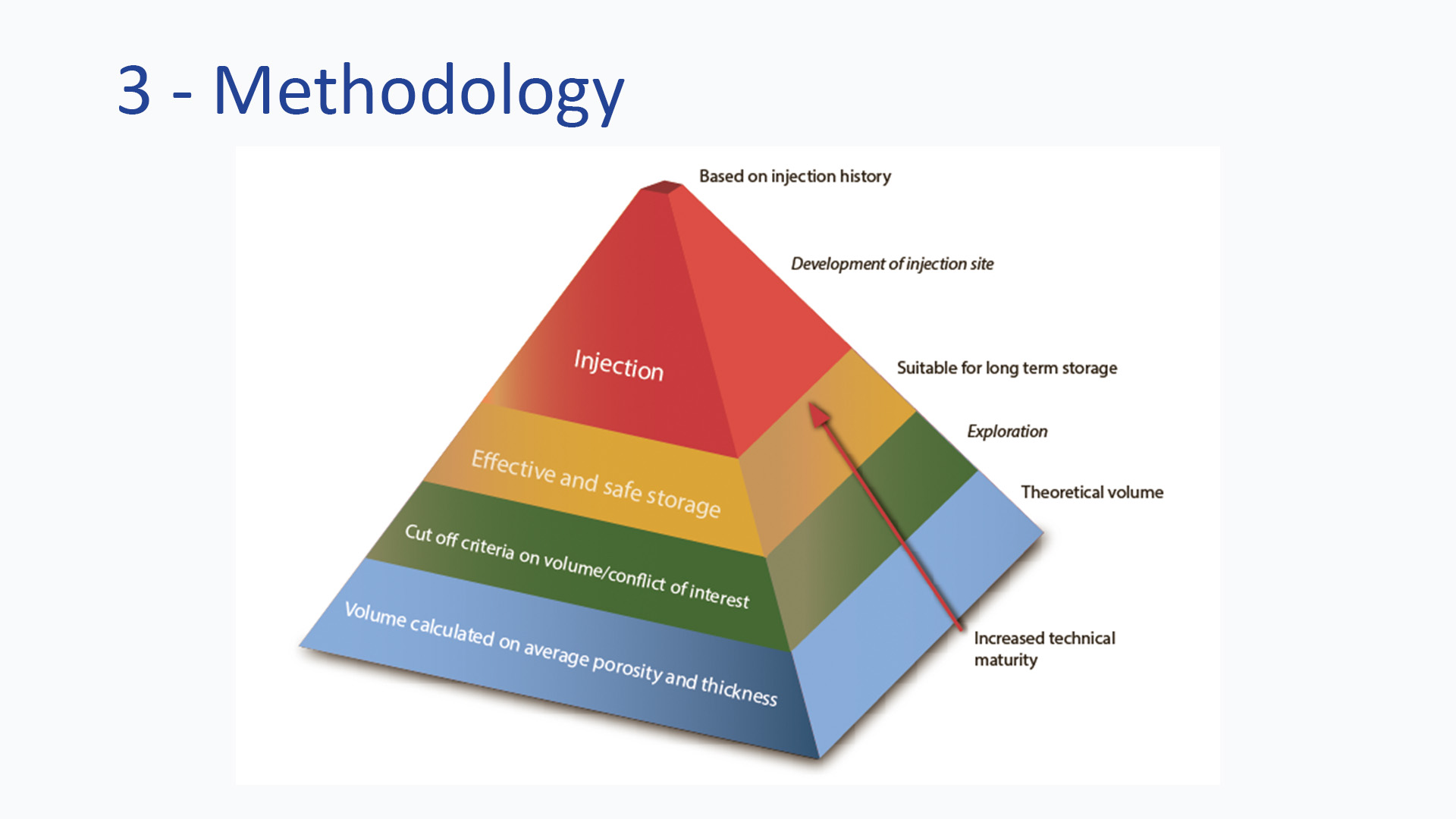

NPD’s approach for assessing the suitability of the geological formations for CO2 storage is summed up in this flowchart. The intention is to identify, in a systematic way, the aquifers and which aquifers are prospective in terms of large-scale storage of CO2.

In subsequent steps in the workflow, each poten-tial reservoir and seal identified, are evaluated and characterized for their CO2 storage prospectivity. Based on this, the potential storage sites are mapped and the storage capacity is calculated. The evaluation is based on available data in the given areas. This evaluation does not provide an economic assessment of the storage sites.

Fig.3.13

Fig.3.14

CO2 can be stored in produced oil and gas fields, or in saline aquifers. In a producing oil field, CO2 can be used to combine storage with enhanced recovery. A depleted gas field can be used for CO2 storage, which will increase the pore pressure in the reservoir. There may be an option to recover some of the remaining natural gas during the CO2 injection. Even if EOR is not the purpose, oil and gas fields can be used for CO2 injec-tion and storage.

In saline aquifers, CO2 can be stored as dissolved CO2 in the water phase, free CO2 or residual (trapped) CO2 in the pores.

When fluid is injected into a closed or half-open aquifer, pressure will increase. The relation between pressure and injected volume depends on the compressibility of the rock and the fluids in the reservoir. The solubility of CO2 in the dif-ferent phases will also play a part. Safe injection of CO2 or any other fluid requires that the injection pressure in the reservoir is less than the fracturing pressure. Pressure increase can how-ever be mitigated by production of formation water. The fracturing pressure depends on the state of stress in the bedrock and is typically 10-30 % lower than the lithostatic pressure. Fracturing gradients were estimated by comparing pore pressures in overpressured reservoirs with data from leak-off tests. Storage capacity depends on several factors, primarily the reservoir pore volume and the fracturing pressure. It is important to know if there is communication between multiple reservoirs, or if the reservoirs are in communication with larger aquifers. The CO2 will preferably be stored in a supercritical phase to take up the least possible volume in the reservoir.

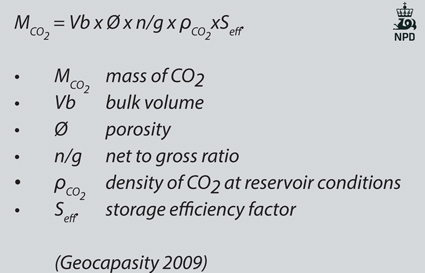

For saline aquifers, the amount of CO2 to be stored can be determined using the following formula:

Seff is calculated as the fraction of stored CO2 relative to the pore volume. The CO2 in the pores will appear as a mobile or immobile phase (trapped). Most of the CO2 will be in a mobile phase. Gradually, some CO2 will be dissolved in the water and simulations show that approximately 10-20% of the CO2 will behave in this manner. When injection in an aquifer stops, CO2 may continue to migrate in the aquifer, and the water will follow, trapping some of the CO2 behind the water. The trapped gas saturation can reach about 30% depending on how long the migration continues. The diffusion of CO2 into the water will be small, but may have an effect over a long time period.

The injection rate will depend on the permeabil-ity and how much of the reservoir is exposed to the injection well. The number of wells needed to inject a certain amount of CO2 will depend on the size of the reservoir and the injectivity.

For a homogenous reservoir with a permeability of 200mD and reservoir thickness of 100m, the storage efficiency in a closed system is simulated to be 0.4 to 0.8%, with a pressure increase of 50 to 100 bar. As shown in the figure, a pressure increase between 50 and 100 bar may be acceptable for reservoirs between 1500 and 3000m, but this must be evaluated carefully for each reservoir.

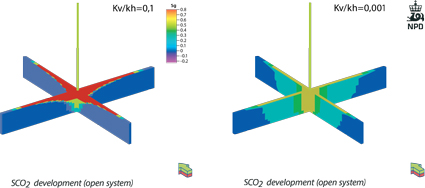

For a homogenous reservoir with a permeability of 200mD and reservoir thickness of 100m, the stor-age efficiency in a closed system is simulated to be 0.4 to 0.8%, with a pressure increase of 50 to 100 bar. As shown in the figure, a pressure increase between 50 and 100 bar may be acceptable for reservoirs between 1500 and 3000m, but this must be evaluated carefully for each reservoir. constant during CO2 injection, as the water will be pushed beyond the boundaries of the reservoir. The CO2 stored will be the amount injected until it reaches the boundaries. The storage efficiency will in this case be ~5 % or more, depending primarily on the relationship between the vertical and horizontal permeability. A low vertical to horizontal permeability ratio will distribute the CO2 better over the reservoir than a high ratio. This is illustrated in the model below of a horizontal reservoir with injection for 50 years.

For abandoned oil and gas fields, the amount of CO2 that can be stored depends on how much of the hydrocarbons have been produced, and to what extent the field is depleted.

The gas fields will normally have low pressure at abandonment, and the oil fields will have a low oil rate and high water cut. The oil fields may have an EOR The gas fields will normally have low pressure at abandonment, and the oil fields will have a low oil rate and high water cut. The oil fields may have an EOR calculated as the volume of CO2 which can be injected to increase pore pressure from abandonment pressure up to initial pressure. For an oil reservoir, CO2 can be stored by allowing pressure increase or by producing up to initial pressure. For an oil reservoir, CO2 can be stored by allowing pressure increase or by producing.