Reduced emissions in the Ekofisk area

Based on input from ConocoPhillips:

The Ekofisk area comprises Eldfisk and Embla as well as Ekofisk. These fields have an integrated infrastructure for production, water injection and power supply. Ekofisk also serves as a transport hub for output from other fields.

In connection with the Ekofisk II development in 1998, major changes were made to power supply in the area. The old turbines were replaced by modern low-NOx units with higher efficiency and lower emissions.

Heat recovery from turbine exhaust fumes, shutting down four old fields and diverting Statpipe around Ekofisk also helped to reduce CO₂ emissions from the area by more than a million tonnes.

Since then, several measures to enhance energy efficiency have been implemented to cut emissions even more. These involve:

- installing low-NOx turbines and a heat recovery plant with a steam turbine and associated generator to exploit waste heat from power-generating turbine exhausts

- measures to enhance energy efficiency related to water injection

- changing the operating philosophy for gas exports and using a single gas compressor rather than two when conditions permit

- installing transmission cables between facilities to ensure the most energy-efficient power supply in the area.

The two power cables alone provide annual CO₂ emission cuts in the order of 25 000 tonnes. A third cable will become operational in 2019, tying all the Ekofisk-area facilities into a single electricity supply grid which permits further optimisation. Its installation will reduce annual emissions by 900 tonnes of CO₂ and 165 tonnes of NOx.

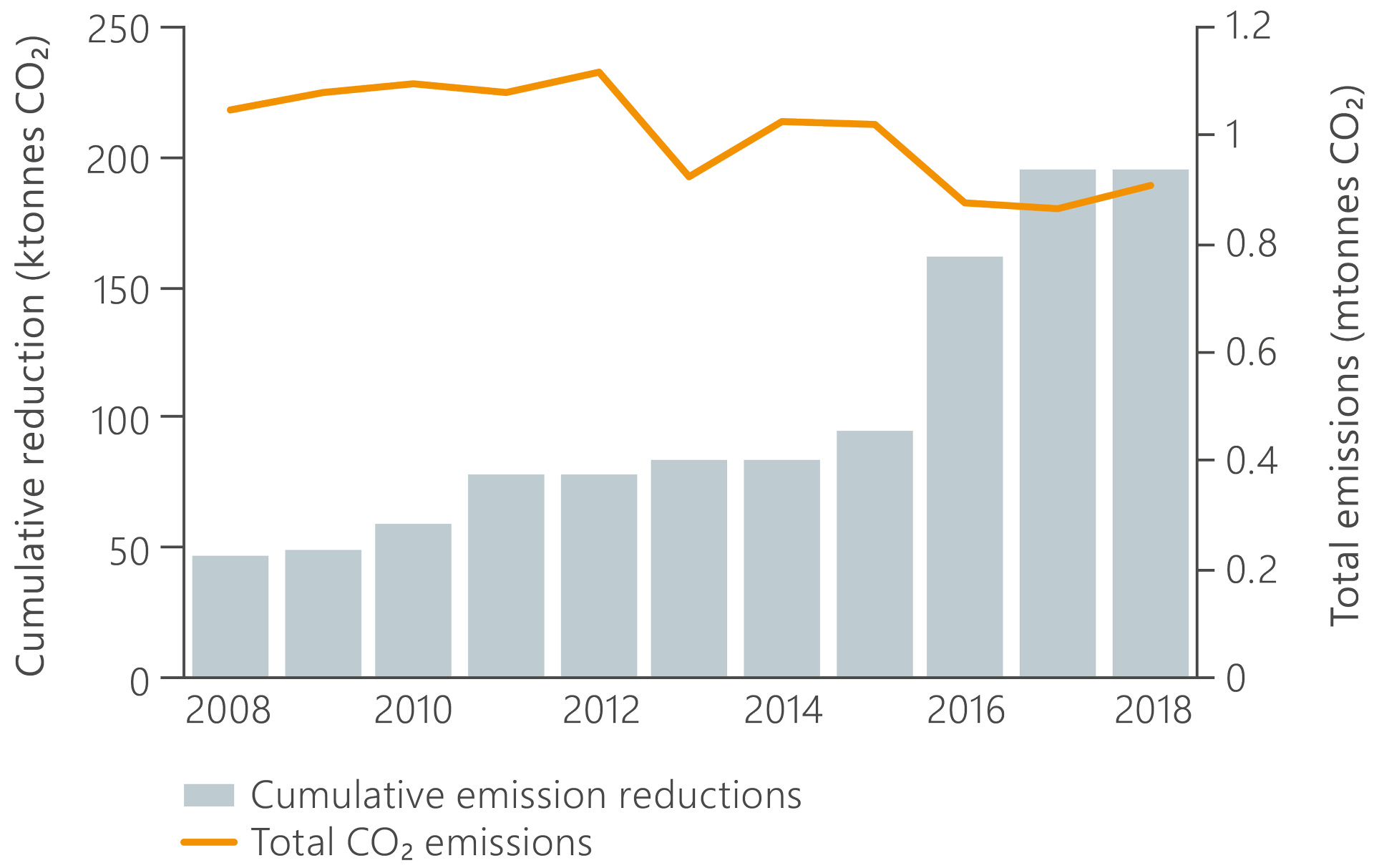

Energy production in the Ekofisk area is based today on the best available technology (BAT), which comprises low-NOx turbines and several heat-recovery units. Enhancing energy efficiency and making modifications have cut emissions over the past decade by 13 per cent, or about 150 000 tonnes of CO₂ since 2008.

Figure 4.6 Total emissions and accumulated emission reductions in the Ekofisk area, 2008-18. Source: ConocoPhillips.

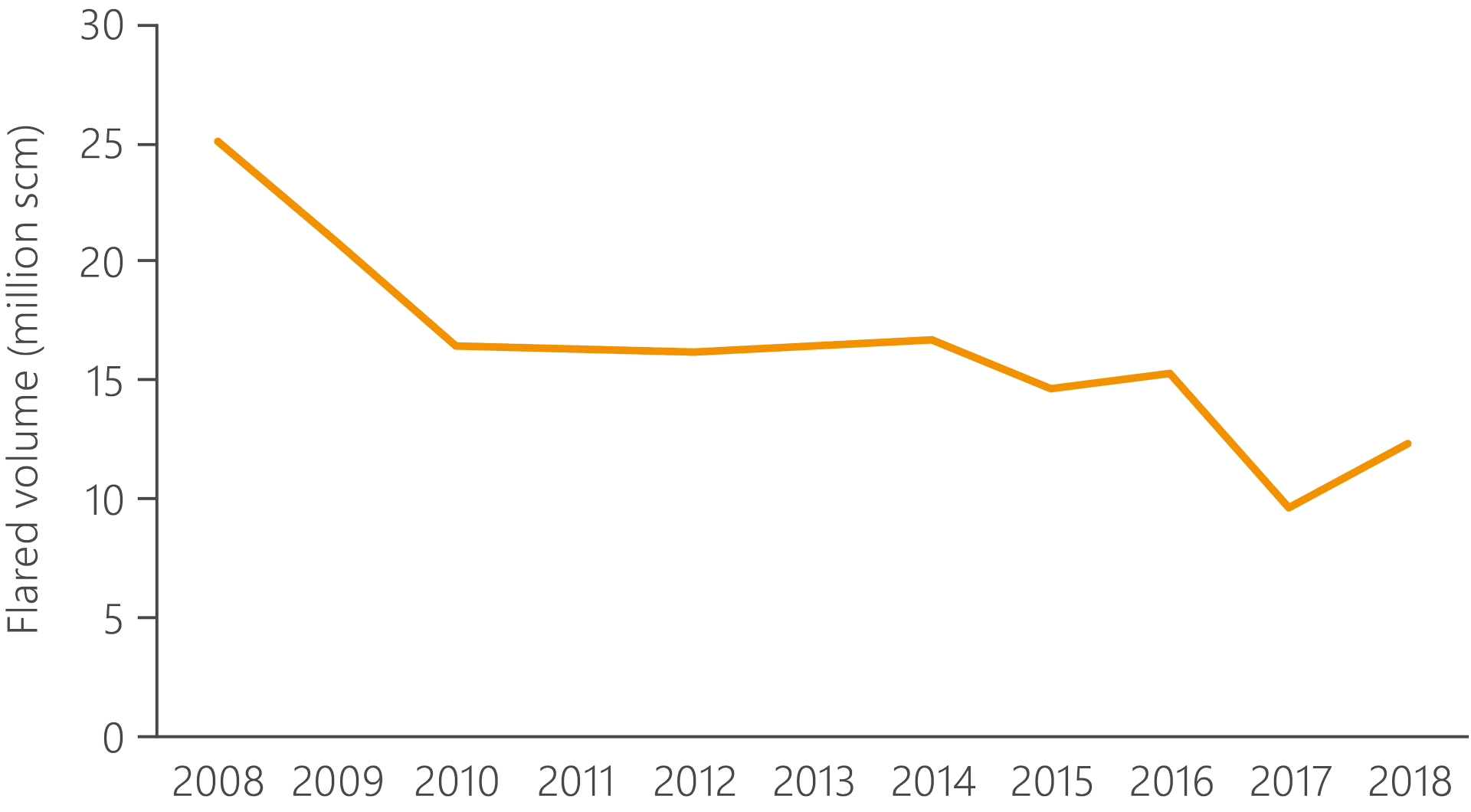

Some 20 million scm of gas was flared annually in the Ekofisk area during 2004-09. A number of measures, such as shutting down a flare, introducing targets for flaring reductions, reintroduction of the pilot flare and installation of flare gas recompression, have substantially reduced this. Over the past couple of years, 10-12 million scm of gas have been flared – almost a halving compared with the 2009 level.

Figure 4.7 Quantity of gas flared on fields in the Ekofisk area. Source: ConocoPhillips.

Work is under way on even greater reductions, in part through the installation of a new flare gas compressor. Expected annual emission cuts from this project are in the order of 27 000 tonnes of CO₂. That corresponds in total to some nine million scm of gas which can be sold rather than flared.